Contrary to the romantic ‘loft-style’ dream, a converted mill apartment is an industrial machine repurposed for living, with unique physical and financial liabilities.

- The very features you love—exposed brick and high ceilings—are often the source of significant thermal and acoustic problems.

- Heritage status (like Grade II listing) severely restricts modifications, making simple upgrades like window replacement complex and costly.

- The building’s industrial past can leave a legacy of structural weaknesses and invisible hazards a standard survey might overlook.

Recommendation: Approach a mill conversion purchase not as a standard homebuyer, but as an industrial archaeologist, investigating the building’s material legacy before committing.

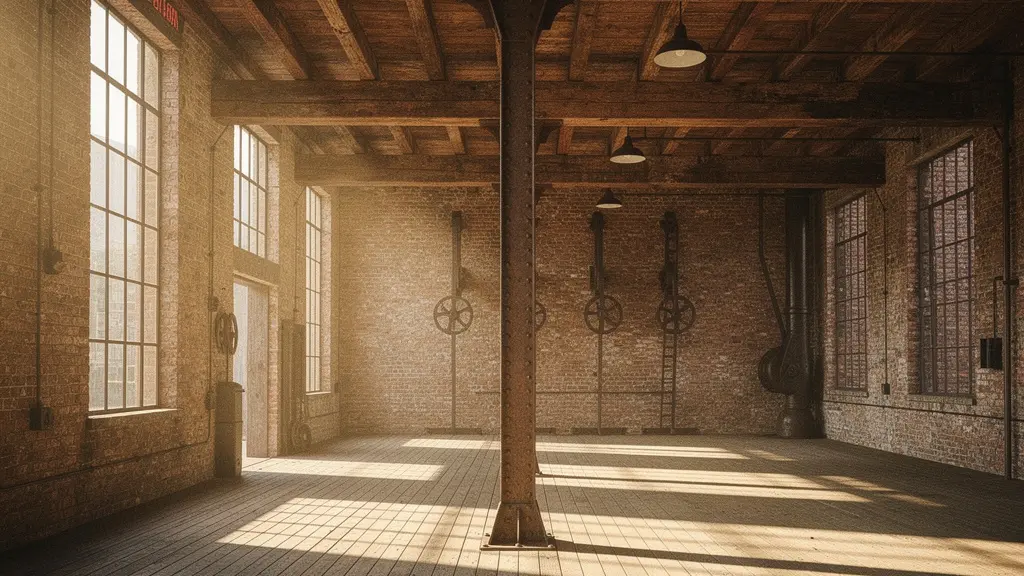

The allure is undeniable. Exposed brick walls that tell a story, vast original windows flooding the space with light, and soaring ceilings crisscrossed with heavy timber beams. Buying a converted textile mill apartment feels like acquiring not just a home, but a piece of industrial heritage. For potential homebuyers drawn to this “loft style,” the aesthetic often eclipses the practical realities. The brochures sell a lifestyle of character and space, but rarely mention the unique challenges that come with adapting a 19th-century industrial building for 21st-century domestic life.

From a property surveyor’s perspective, these buildings are fascinating but complex. They were never designed for quiet, thermally-efficient living. They were built to house colossal, vibrating machinery and withstand industrial processes. The very elements that create their charm—the raw materials and cavernous spaces—are often the root of significant, non-obvious costs. Standard advice about checking for damp or getting a basic survey is insufficient here. To truly understand what you’re buying, you must look past the aesthetic and analyse the building as an engineer would.

This article moves beyond the surface-level appeal. We will not be celebrating the style, but dissecting the substance. The true key to a successful purchase lies in understanding the building’s original function and material physics. This is the only way to anticipate the significant, non-obvious costs related to acoustics, thermal dynamics, and structural integrity that a standard viewing will never reveal. We’ll explore the real-world implications of those beautiful brick walls, the truth about noise transfer, the legal maze of listed building consent, and the invisible hazards that could be lurking beneath the newly-sanded floors.

This guide provides a surveyor’s-eye view of the critical factors to investigate before you fall in love with the loft lifestyle. Read on to discover the questions you should be asking.

Summary: Uncovering the True Cost of Mill Apartment Living

- Why Exposed Brick Walls Make Your Heating Bill Skyrocket in Winter?

- Wooden Beams and Neighbors: How to Deal With Noise Transfer in Conversions?

- Grade II Listed Status: Can You Change the Windows in Your Mill Apartment?

- From Cotton to Condos: What Was Your Apartment Used for in 1890?

- Lighting High Ceilings: How to Create Intimacy in a Cavernous Industrial Space?

- Why Humidity Fluctuations Destroy Victorian Woodwork Within Months?

- Rotting Floors and Asbestos: How to Spot Invisible Hazards in Derelict Mills?

- Is Urban Exploration Legal in the UK: Trespass Laws Explained?

Why Exposed Brick Walls Make Your Heating Bill Skyrocket in Winter?

That beautiful exposed brick wall is the hallmark of industrial chic, but it’s also a primary source of heat loss. Bricks are dense and have high thermal mass, meaning they absorb and store heat well. However, they are poor insulators. In a building designed as a factory, this wasn’t a concern. For a modern home, it means your interior heat is constantly being wicked away to the cold exterior. Research shows that a proper insulating layer behind a brick veneer can reduce heat transfer by up to 50%, a layer that is, by definition, missing in an “exposed brick” design.

The more critical issue, however, is the prevalence of thermal bridges. These are pathways of high thermal conductivity that allow heat to flow out of the building with little resistance. In mill conversions, they are typically formed by original structural elements. Steel beams, concrete floor slabs, or metal window lintels that pass through the brickwork from inside to out act like highways for heat to escape. These spots become noticeably colder than the surrounding wall, leading to condensation, localised damp, and even mould growth.

A standard energy performance certificate (EPC) may not fully capture the impact of these specific structural thermal bridges. While developers are required to meet building regulations, the methods used can vary in effectiveness. Without intrusive investigation, it’s difficult to know how well junctions between original and new materials have been insulated. The result is a home that feels perpetually chilly in certain areas and requires significantly more energy—and money—to keep warm.

Wooden Beams and Neighbors: How to Deal With Noise Transfer in Conversions?

The heavy, rough-hewn wooden beams that define a mill’s interior are part of its structural soul. They carried the load of floors packed with machinery. Unfortunately, they also carry sound with incredible efficiency. In their original state, these buildings had no need for acoustic separation between floors. The roar of looms would have drowned out everything else. Today, that same structural continuity means that impact noise—footsteps, dropped items, moving furniture—from your upstairs neighbour can travel directly through their floor, along the shared beams, and radiate into your apartment.

This is a common and significant complaint in mill conversions. Developers must add acoustic insulation to meet modern building regulations for airborne noise (like voices or music). However, effectively mitigating low-frequency impact noise in a timber-frame industrial building is far more challenging and expensive. Quick-fix solutions like simply laying thick carpet over the original floorboards are often inadequate. Proper acoustic isolation requires creating a “floating floor” system or using resilient insulation materials that decouple the new floor surface from the original structure, solutions that are not always implemented to the highest standard.

The visual appeal of exposed beams and floorboards often comes at a direct cost to your peace and quiet. As an illustrative example, the conversion of the huge Massachusetts Mills into over 400 apartments faced immense acoustic challenges due to the open-plan design and hard surfaces, necessitating extensive and specialised sound mitigation strategies. When viewing a property, listen carefully. If possible, ask to be in the apartment while someone walks around in the one above.

The beautiful texture of these original beams hides their role as a conduit for sound. The vibrations from your neighbours can travel along these structural elements just as easily as they once carried the vibrations of industrial machinery. It is a core part of the building’s material legacy that you will inherit.

Grade II Listed Status: Can You Change the Windows in Your Mill Apartment?

Many historic mills are protected with a Grade II listed status, a designation that aims to preserve their architectural character. This has profound implications for homeowners, especially when it comes to windows. The large, single-glazed, often metal-framed windows are a key part of the industrial aesthetic, but they are notoriously inefficient, leading to drafts and high heating costs. The logical solution would be to replace them with modern double or triple glazing. However, with a listed building, it’s not that simple.

Any alteration to the external appearance of a listed building requires specific consent from the local planning authority’s conservation officer. Replacing original windows is almost always a non-starter. The primary goal of the listing is to preserve the original fabric. This creates a direct conflict between conservation and performance. You are often left with a few options, each with its own significant cost and compromise. Secondary glazing—installing a discreet second pane on the inside—is usually the most accepted solution, but it can be cumbersome and affect the clean lines of the window reveals. High-performance historic replica windows are sometimes permitted, but they are extremely expensive. A study on a similar project found that high-performance historic replica windows and heat pumps can reduce greenhouse gas emissions, but the upfront cost is substantial.

Understanding your options and their associated costs is critical before you buy. Do not assume you can simply upgrade the windows. You are buying into a set of legal restrictions that prioritise the building’s historical appearance over your thermal comfort and energy bills.

| Option | Cost Range | Energy Performance | Heritage Compliance |

|---|---|---|---|

| Historic Replica Windows | High ($800-1500/window) | Good (U-value 0.3-0.4) | Fully Compliant |

| Secondary Glazing | Moderate ($300-600/window) | Very Good (Combined U-value 0.2-0.3) | Usually Acceptable |

| Vacuum Insulated Glass (FINEO) | Very High ($1000-2000/window) | Excellent (U-value 0.7) | Case-by-case approval |

| Keep Original Single Pane | None | Poor (U-value 5.0+) | Fully Compliant |

From Cotton to Condos: What Was Your Apartment Used for in 1890?

Knowing the history of your building is more than a romantic curiosity; it’s a crucial part of your due diligence. The specific industrial process that took place in the space your apartment now occupies can have a direct impact on its current condition. This is the practice of industrial archaeology. Was your apartment on a floor used for carding, which involved heavy, vibrating machinery that could have stressed the floor joists? Or was it a finishing area, where chemicals and dyes were used that may have seeped into the floorboards and underlying structure over decades?

For example, floors that housed looms are often subtly sloped to allow for oil runoff, a feature that can be a surprise in a modern living room. Areas used for wet processes like dyeing may have a legacy of moisture damage in the timbers that has been cosmetically covered over. Tracing the building’s past use can provide clues to potential future problems. You can start by examining Sanborn Fire Insurance Maps from the period, which often detail the use of each floor of a factory, or by checking local historical society archives for production logs and conservation reports filed during the conversion.

This history gives the building its unique character and is often a point of pride for developers and residents. As the architects for a similar project noted:

The building, which opened in the 1800s as a textile mill, is named after the first woman to spin cotton in the United States.

– FILLAT+ Architecture, Oella Mill Apartments Project Description

While this history is a selling point, a surveyor sees it as a road map to potential structural quirks and material issues. It’s your job as a prospective buyer to read that map carefully and understand what the story of the walls and floors might mean for your future maintenance bills.

Lighting High Ceilings: How to Create Intimacy in a Cavernous Industrial Space?

One of the most dramatic features of a mill conversion is the ceiling height. Twenty-foot ceilings are not uncommon, creating a sense of volume and space that is impossible to find in modern construction. However, this “pro” quickly becomes a “con” when it comes to lighting. A single, central ceiling fixture is wholly inadequate; it will leave the room feeling like a poorly lit warehouse, with the living space at the bottom lost in gloom. Creating a sense of intimacy and functional light in such a cavernous space is both an art and a significant expense.

Effective lighting in a loft requires a layered approach. This involves using multiple light sources at different heights to define zones and create atmosphere. For example, a successful scheme might involve track lighting mounted on beams ten feet up to wash the walls, combined with dramatic, low-hanging pendant lights over a dining table or kitchen island to create a focal point and bring the light down to a human scale. Additional floor lamps and table lamps are then needed to create warm, intimate pools of light for reading or relaxing.

This multi-layered solution can be costly to install and operate. It often requires specialist electrical work to run wiring to the correct points on high ceilings or exposed beams. The fixtures themselves can be expensive, and the sheer number of bulbs required increases energy consumption. Furthermore, the simple act of changing a lightbulb can become a major task, requiring a specialist ladder or scaffolding. What begins as an impressive architectural feature can quickly become a practical and financial headache if not properly considered from the outset.

Why Humidity Fluctuations Destroy Victorian Woodwork Within Months?

The original Victorian-era woodwork in a mill—the massive timber beams, thick floorboards, and structural joists—has survived for over a century because it existed in a relatively stable, unheated environment. Introducing modern central heating and lifestyles creates a new and dangerous enemy: dramatic humidity fluctuations. The combination of cold, inefficient single-glazed windows and the building’s inherent thermal properties creates a unique microclimate. The brickwork’s thermal mass effect can create a 5-8°C differential between the air temperature and the wall surface temperature, leading to condensation.

In winter, heating the air causes it to dry out, making the old, dry timber shrink. Meanwhile, condensation forms on the cold windows and thermal bridges, raising the humidity in those specific areas and causing the wood to swell. This constant cycle of shrinking and swelling puts immense stress on the woodwork. Joints can open up, floorboards can warp and cup, and decorative finishes can crack and peel. A “quick-fix” renovation that simply sands and varnishes the original floors without addressing the underlying humidity issue is a ticking time bomb. The beautiful finish can be ruined within a few seasons.

Properly treating and preserving this timber is a specialist job. It involves ensuring the wood is at a stable moisture content before it’s sealed, and using breathable finishes that can accommodate some natural movement. As a buyer, you must look for the signs of a professional job versus a cosmetic cover-up.

| Proper Treatment Signs | Quick-Fix Red Flags |

|---|---|

| Even, natural wood coloring | Unnaturally dark patches under varnish |

| Smooth, consistent finish | Thick, globby varnish layers |

| No musty odor | Musty smell when humid |

| Stable year-round | Peeling finishes after 6-12 months |

| Professional drying documentation | No treatment records available |

Key Takeaways

- The aesthetic appeal of mill conversions often conceals significant structural and financial liabilities related to thermal performance, acoustics, and heritage restrictions.

- A building’s industrial past is not just history; it’s a blueprint for potential future problems, from floor strain to material contamination.

- A standard property survey is insufficient; a specialist approach is required to identify hidden hazards like dry rot, asbestos, and the true condition of original materials.

Rotting Floors and Asbestos: How to Spot Invisible Hazards in Derelict Mills?

Beyond the visible issues, the real costs of a mill conversion can be hidden deep within the structure. Decades of industrial use, followed by periods of neglect before conversion, create the perfect conditions for serious problems. One of the most critical is dry rot. If a roof leak went unrepaired for years, water could have penetrated deep into the floor structures. Once established, dry rot can spread silently through timber, reducing structural beams to fibrous dust behind a thin veneer of healthy-looking wood.

Another major invisible hazard is asbestos. It was a common insulation material used in the 20th century for wrapping pipes and boilers in industrial settings. While developers are required to perform hazardous material surveys and remove accessible asbestos during conversion, it can be impossible to guarantee that all of it has been found and safely remediated, especially in inaccessible voids or wrapped around pipework within walls. Discovering asbestos after you’ve purchased can lead to staggeringly high removal costs and health risks.

A surveyor’s job is to look for the subtle tell-tale signs. Water stains on ceilings below wooden floors, even if painted over, are a major red flag. Uneven or “bouncy” floors can indicate that joists have been compromised by rot or beetle infestation. When viewing a property, don’t be afraid to perform your own basic checks. These are no substitute for a full structural survey by a specialist experienced in historic industrial buildings, but they can help you spot potential deal-breakers early on.

Your Pre-Purchase Inspection Checklist: Spotting Red Flags

- Perform the ‘bounce test’: Walk firmly across floors, especially away from main beams, feeling for excessive give or sponginess.

- Look for water stains: Check ceilings below wooden floors and around windows for signs of past or present moisture damage, even if painted over.

- Check for level surfaces: Look for noticeable sagging or unevenness in floors and ceilings, which could indicate structural issues.

- Request documentation: Ask for both the structural survey and the hazardous materials report commissioned during the conversion.

- Inspect beam ends: Where possible, examine where exposed beams meet exterior walls for signs of rot, insect damage, or damp.

Is Urban Exploration Legal in the UK: Trespass Laws Explained?

The temptation to “explore” a derelict mill before it’s converted is strong for some enthusiasts, but from a potential buyer’s perspective, this is a dangerous and legally dubious path. In the UK, trespass is a civil matter, not a criminal one, meaning you can’t be arrested for simply being on the land. However, if you cause any damage (which can be as simple as breaking a rotten floorboard), it can become criminal damage. More importantly, these are incredibly dangerous environments, and you would not be insured if you were injured.

So, how can a serious buyer get a feel for the “before” state of a building legally and safely? The answer lies in engaging with the developer. A proactive approach is to request a formal site visit during the very early stages of development. Many developers are happy to accommodate this for serious prospective buyers, as it helps build excitement and a list of off-plan purchasers. This provides the thrill of seeing the raw space, but under controlled and safe conditions.

Case Study: The Judson Mill Pre-Development Access Program

Before the full-scale renovation of Judson Mill, a massive textile factory, the developers took an innovative approach. They offered structured ‘hard hat tours’ during the initial clearing-out and stabilization phases. This allowed potential buyers to walk through the vast, raw industrial spaces safely and legally. It not only built a strong pipeline of interested parties who felt connected to the project from the start but also allowed them to appreciate the scale of the transformation, turning a potentially risky ‘exploration’ into a positive marketing and sales tool.

This kind of sanctioned visit is the intelligent way to assess a building’s raw potential. As one industry advisory notes, it’s about shifting from a risky trespass to a formal inquiry:

Request a pre-conversion site visit with the developer. This provides the thrill of seeing the ‘before’ state, but legally and safely, allowing you to assess the building’s raw potential.

– Construction Industry Advisory, Best Practices for Mill Conversion Site Visits

Ultimately, buying a mill conversion is about informed decision-making, not reckless adventure. The most valuable exploration you can do is through legal documents, structural surveys, and formal site visits, not through a broken window.

To truly protect your investment, the next logical step is to commission a full structural survey from an engineer or surveyor who specializes in historic and industrial buildings. This is the only way to get a complete picture of the property’s health and potential future costs.